I hope everyone appreciates the level of creativity that I applied to coming up with this title. It has been a while since I’ve spent a full day in the garage. I’m always amazed how therapeutical working with wood is. My wife and I recently purchased a Thor Gemini 23 motorhome. It is our first motorhome, and aside from the numerous issues, we love owning a motorhome.

I already made a couple of modifications:

There is a shelf under the sofa bed in the living area. It is incredibly difficult to get to things stored down there, especially once it gets dark outside; the lights don’t light up the inside. I could only think of one solution – a big drawer. As with all modifications, I wanted to ensure it’s not a permanent modification to our Thor Gemini 23. This is also the very first time I’ve used my Rockler box joint jig to create some box joints.

Getting Started (on the base)

Measuring anything is so much easier with my handy Bosch laser measuring tool. So awesome. Measured the width of the shelf.

I do try to avoid the table saw when possible, so I used my trusty DeWalt circular saw.

Checking Fit & Starting Sides

Attaching Sides to Base Plate

Setting up the new Bosch upcut 1/4 router bit on the Rockler box joint jig using my new Kreg setup bars (they are awesome!)

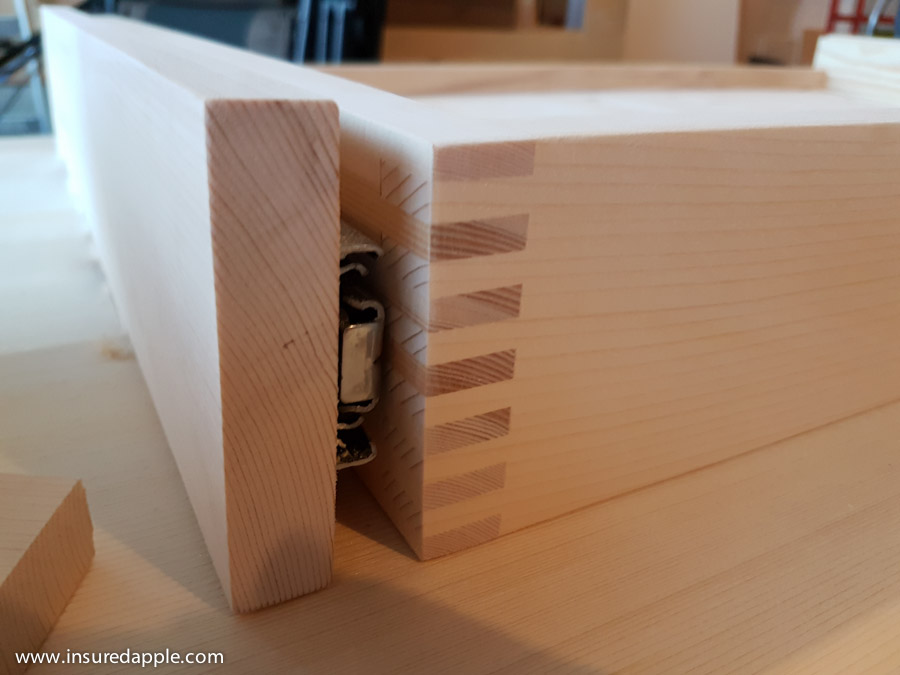

Drawer Rails

There was quite a selection of different rail types. These 22 inch Hickory slide rails felt the best and lock in when closed.

Building the Drawer Frame

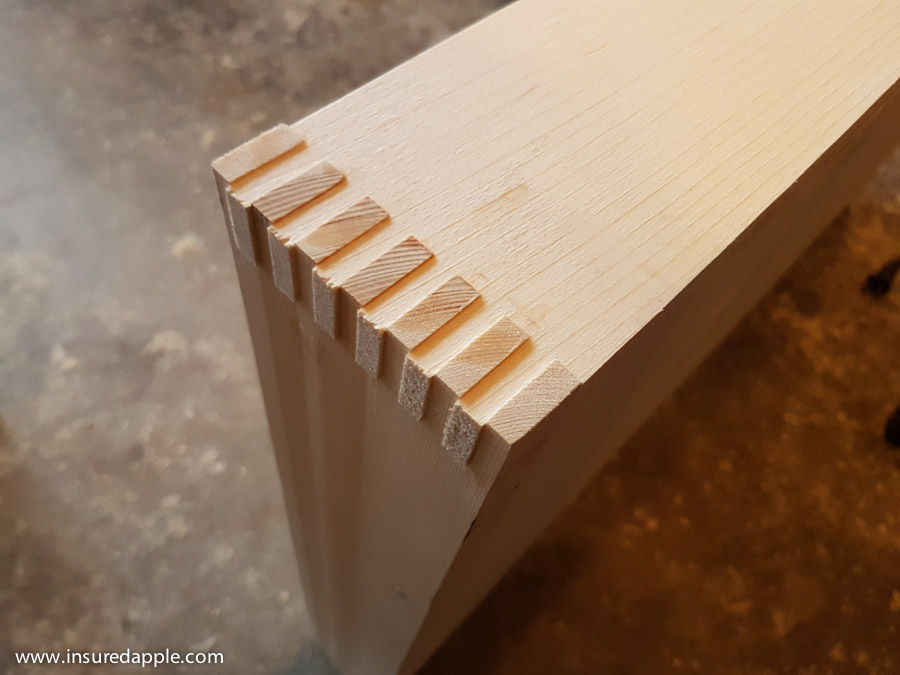

I did some test cuts to make sure the joints would work; using my Rockler Box Joint Jig.

Building the Drawer Floor

Assembly of the Drawer

I sanded down the joints and they turned out really nice. I am genuinely enjoy working with the box joint jig from Rockler.

Leave A Comment